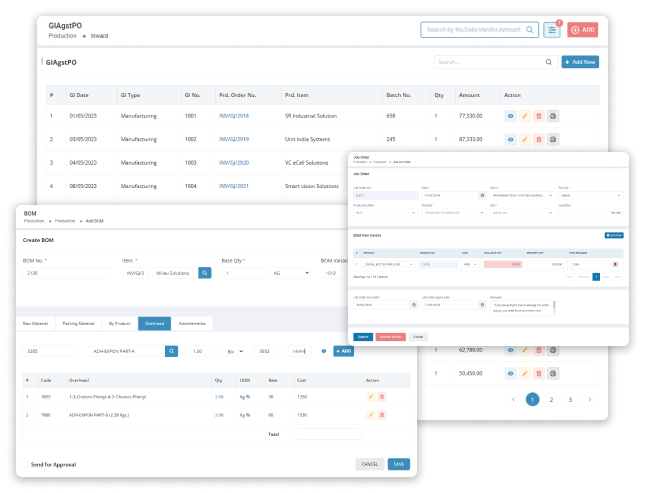

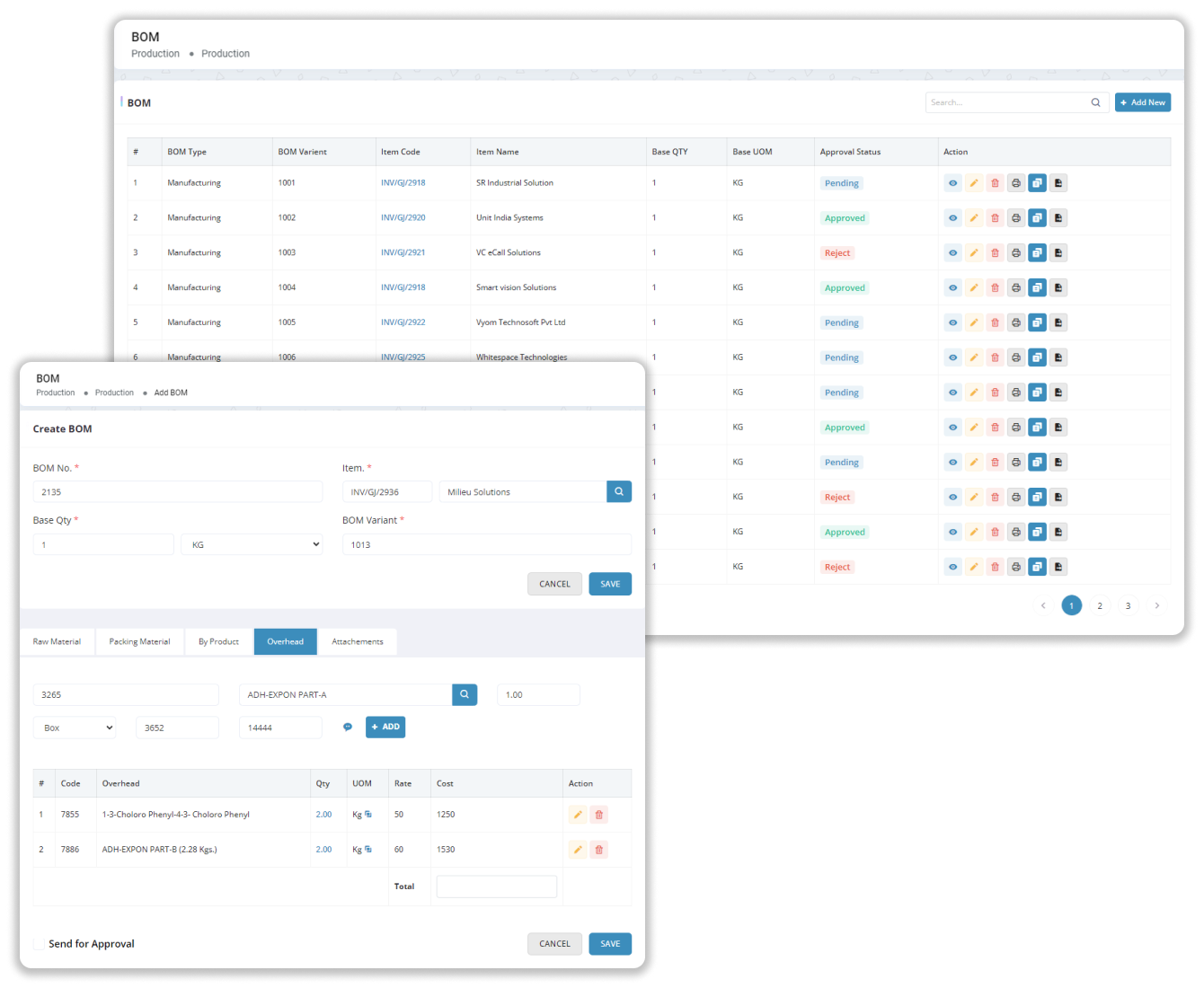

Optimize production operations with our production management solution

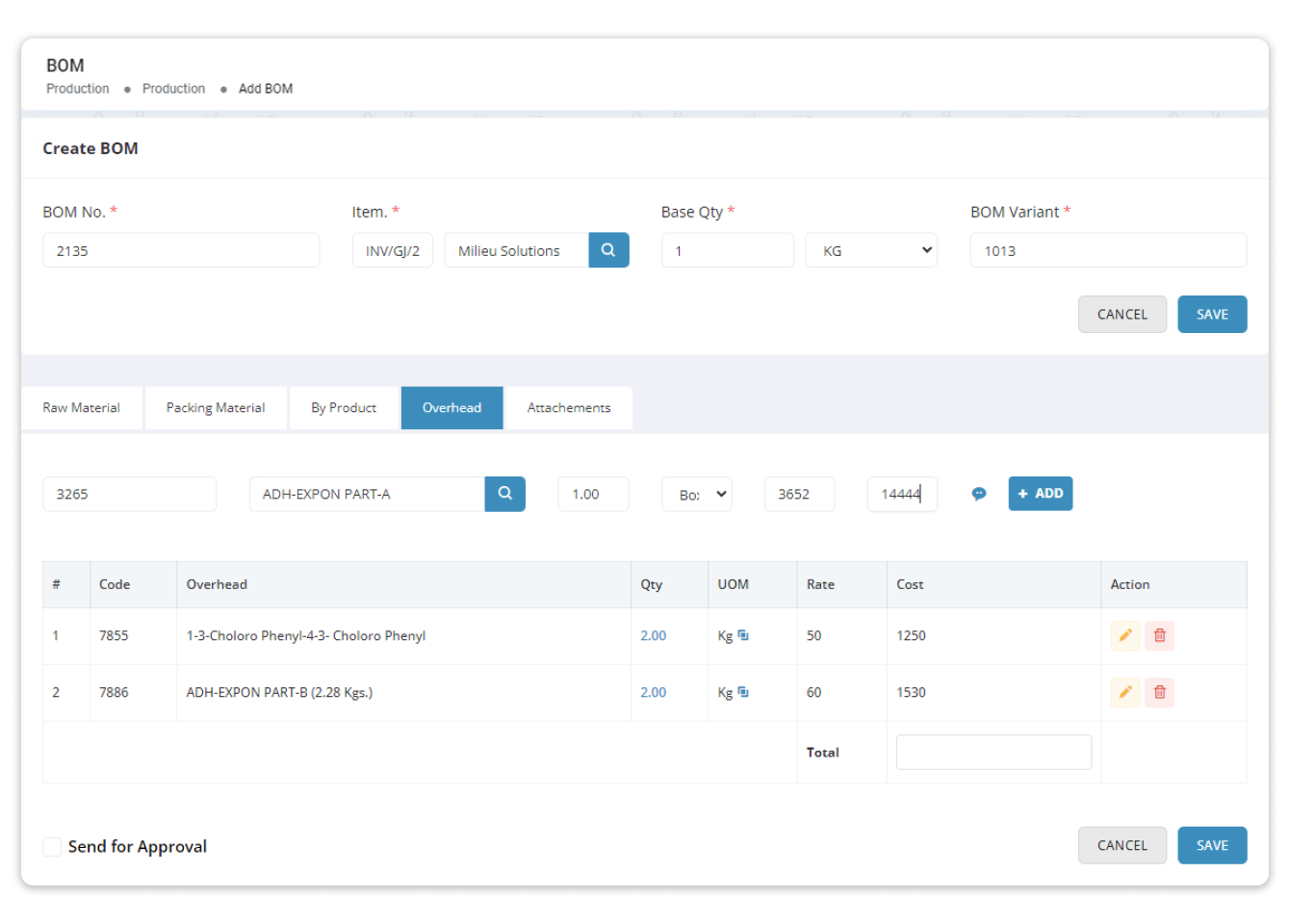

- Cost Control: Effectively manage expenses and allocate resources, ensuring optimal cost control throughout the production process, ultimately maximizing profitability and financial efficiency.

- Enhanced Planning Accuracy: Elevate production planning accuracy by utilizing dynamic BOM features. Precisely forecast material requirements, reducing waste and enhancing overall operational efficiency for better resource utilization.

- Track Changes with Ease: Seamlessly monitor and track changes in the bill of materials in real-time. Ensure transparency and accuracy, facilitating adaptability and responsiveness to evolving production needs and requirements.

- Enhanced Communication: Experience enhanced communication among team members by providing a centralized platform that facilitates information sharing and collaboration on BOM-related information. Improve efficiency and reduce errors through streamlined communication processes.

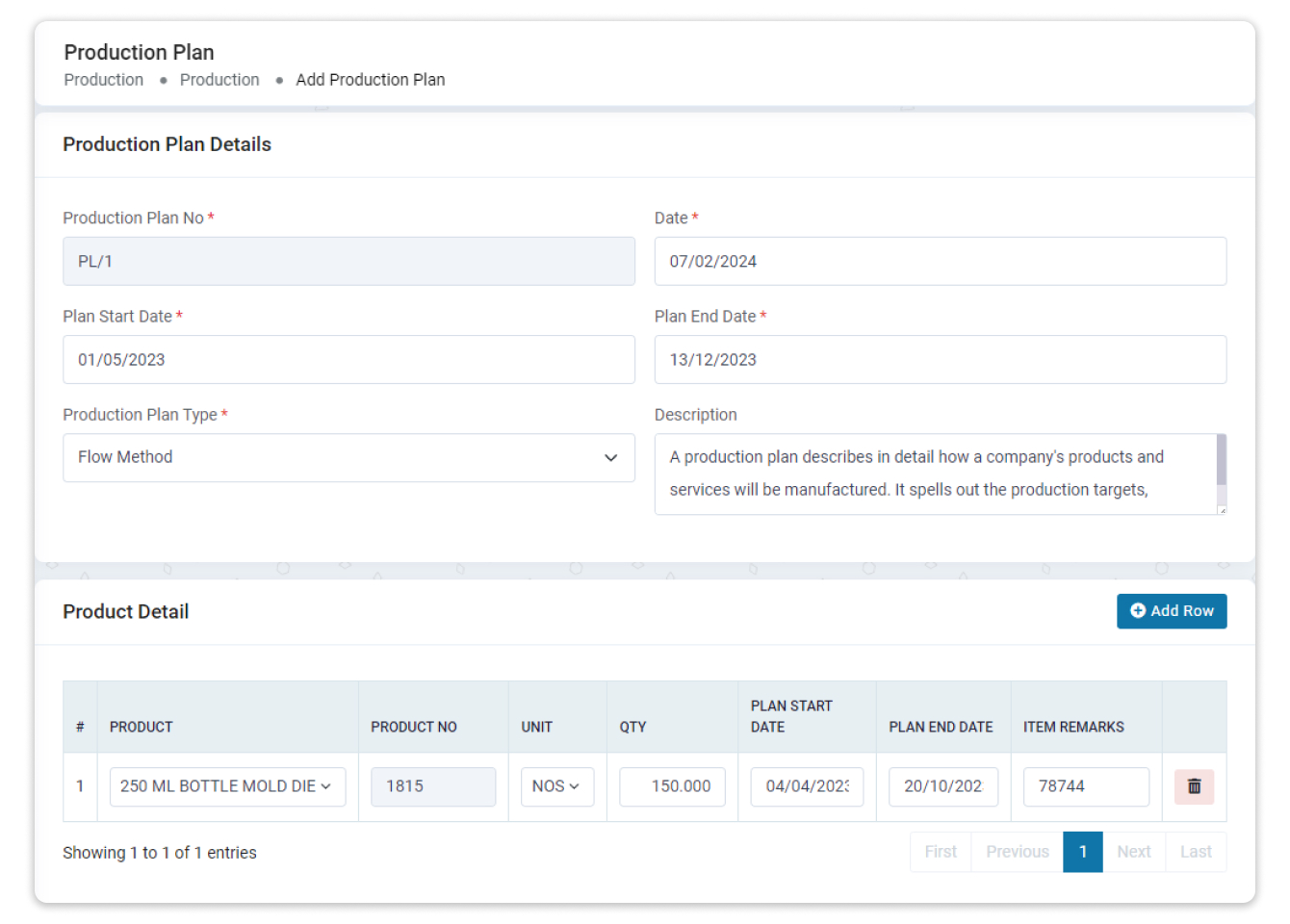

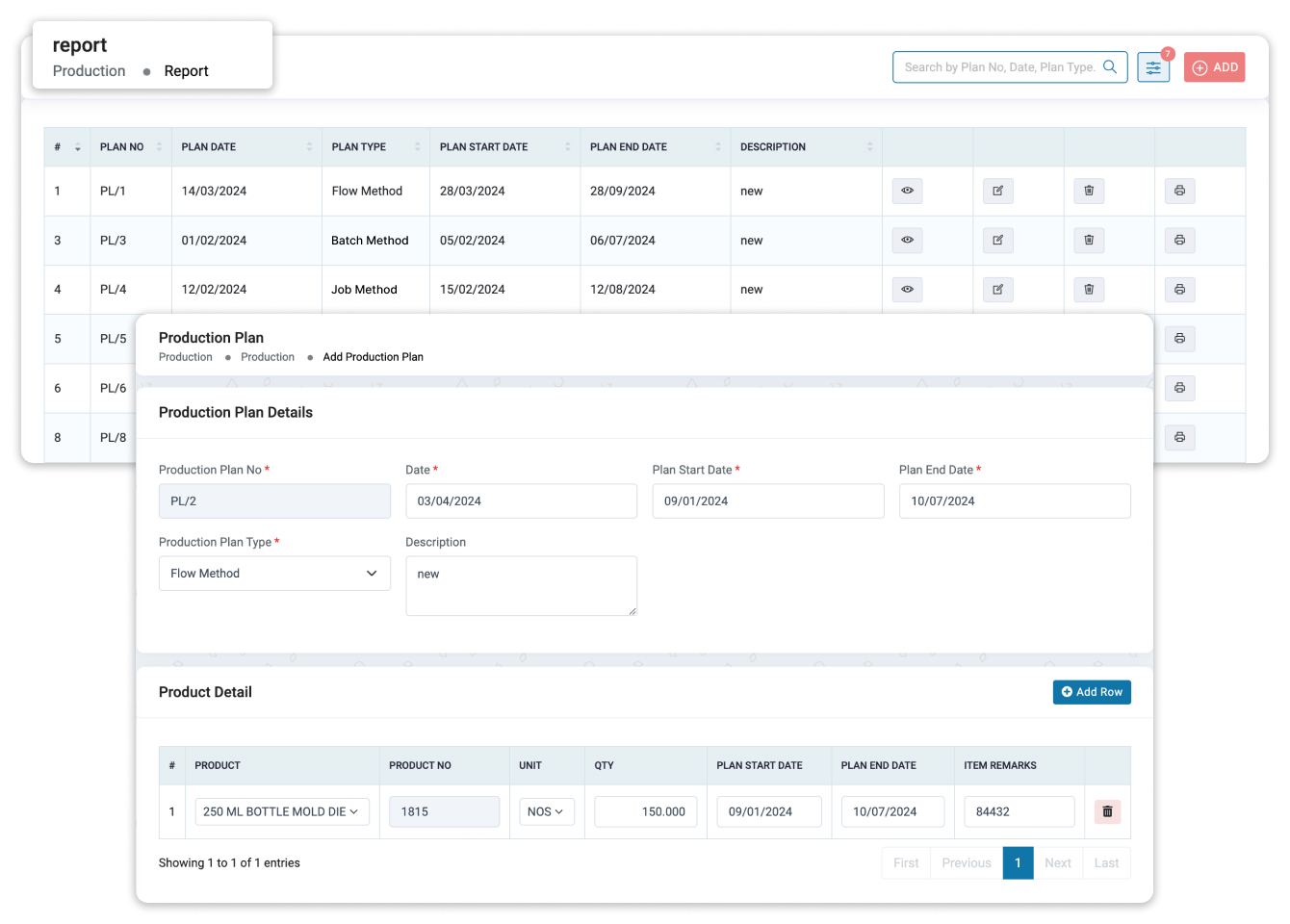

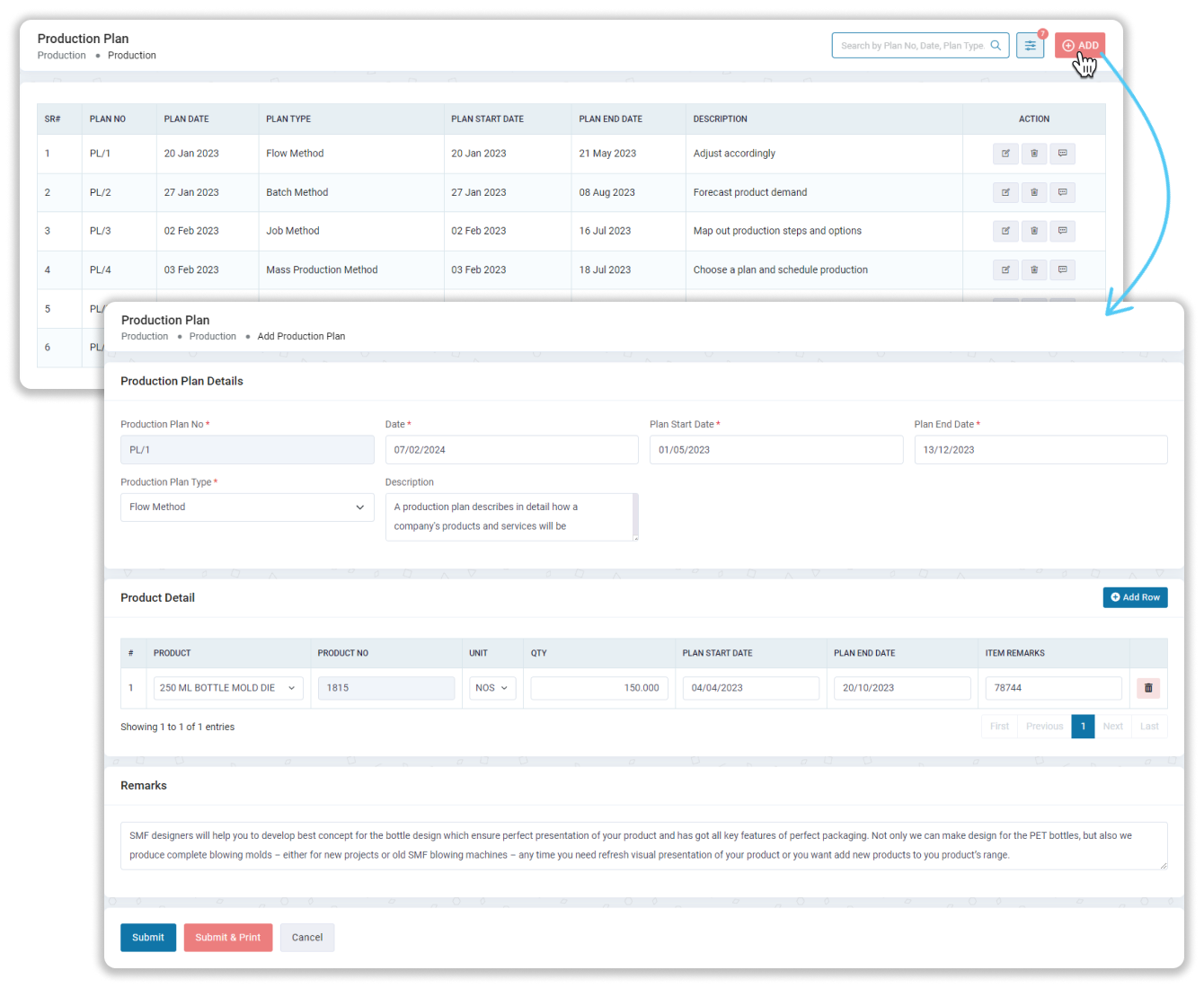

Ensure flawless production processes with the best production planning software

- Strategic Scheduling: Develop precise production schedules, aligning resources for optimal efficiency, and ensuring timely delivery of high-quality products through strategic planning.

- Real-time Visibility: Gain instant insights into production progress that enables proactive decision-making. This also gives you the ability to swiftly adapt and respond to changing circumstances, ultimately enhancing overall operational visibility & control.

- Efficient Resource Allocation: Optimize resource allocation with sheer ease, minimize downtime, and reduce costs. This further ensures maximizing productivity by strategically assigning and managing resources, resulting in a streamlined and cost-effective production process.

- Adaptable Planning: Foster adaptability in production plans, allowing quick adjustments to accommodate evolving demands or unexpected changes. This flexibility ensures a responsive and resilient production strategy, ultimately contributing to improved customer satisfaction and operational success.

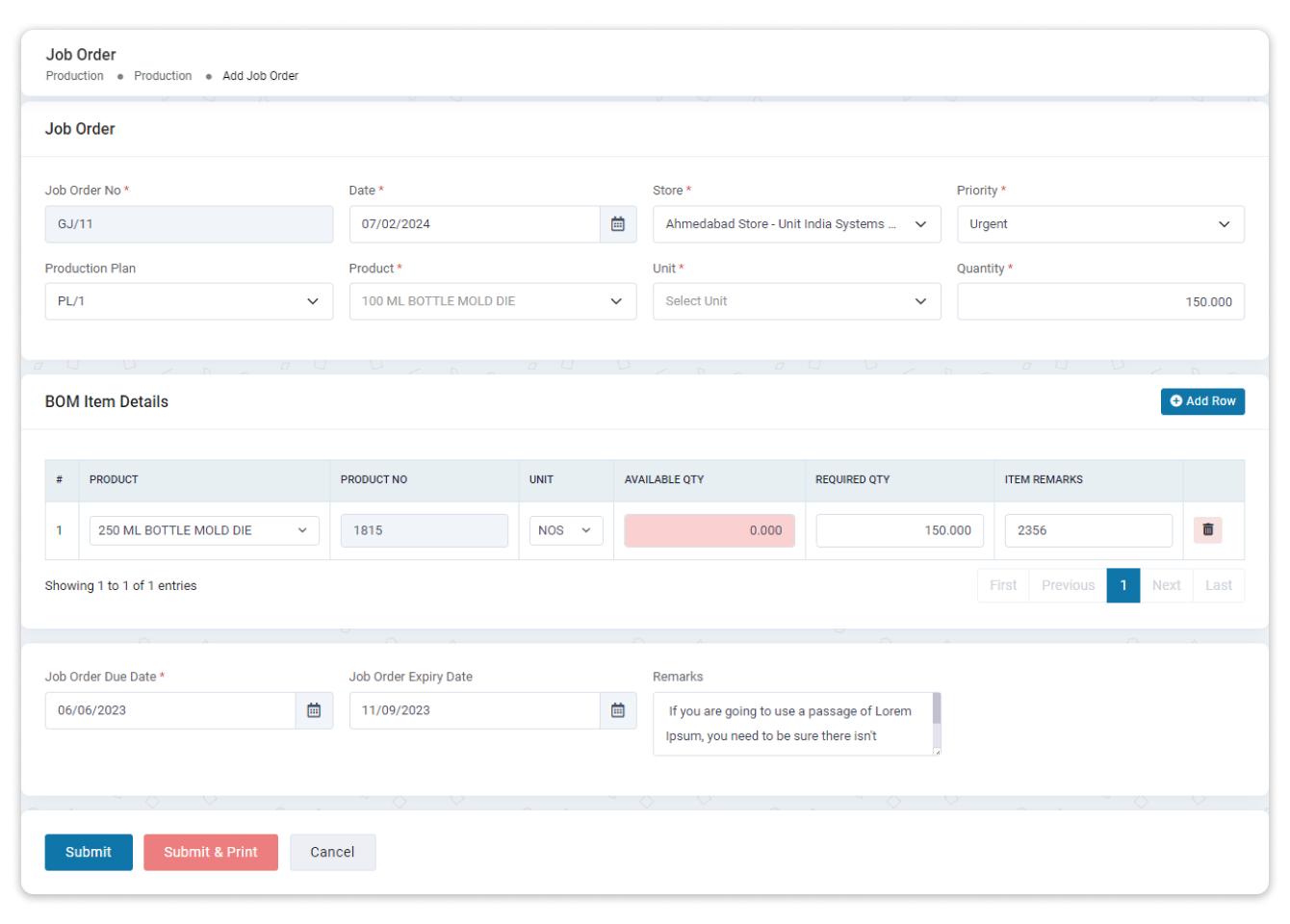

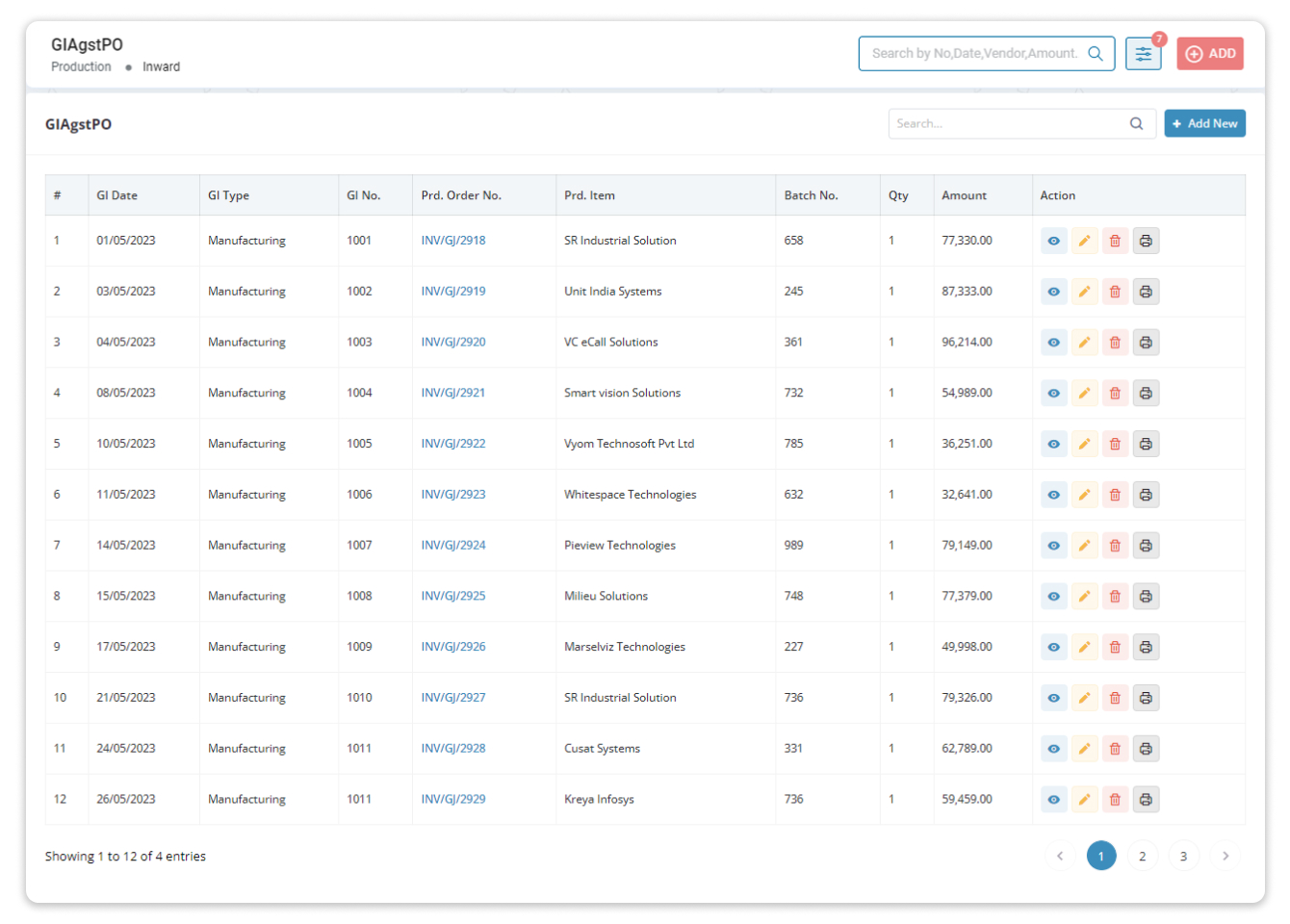

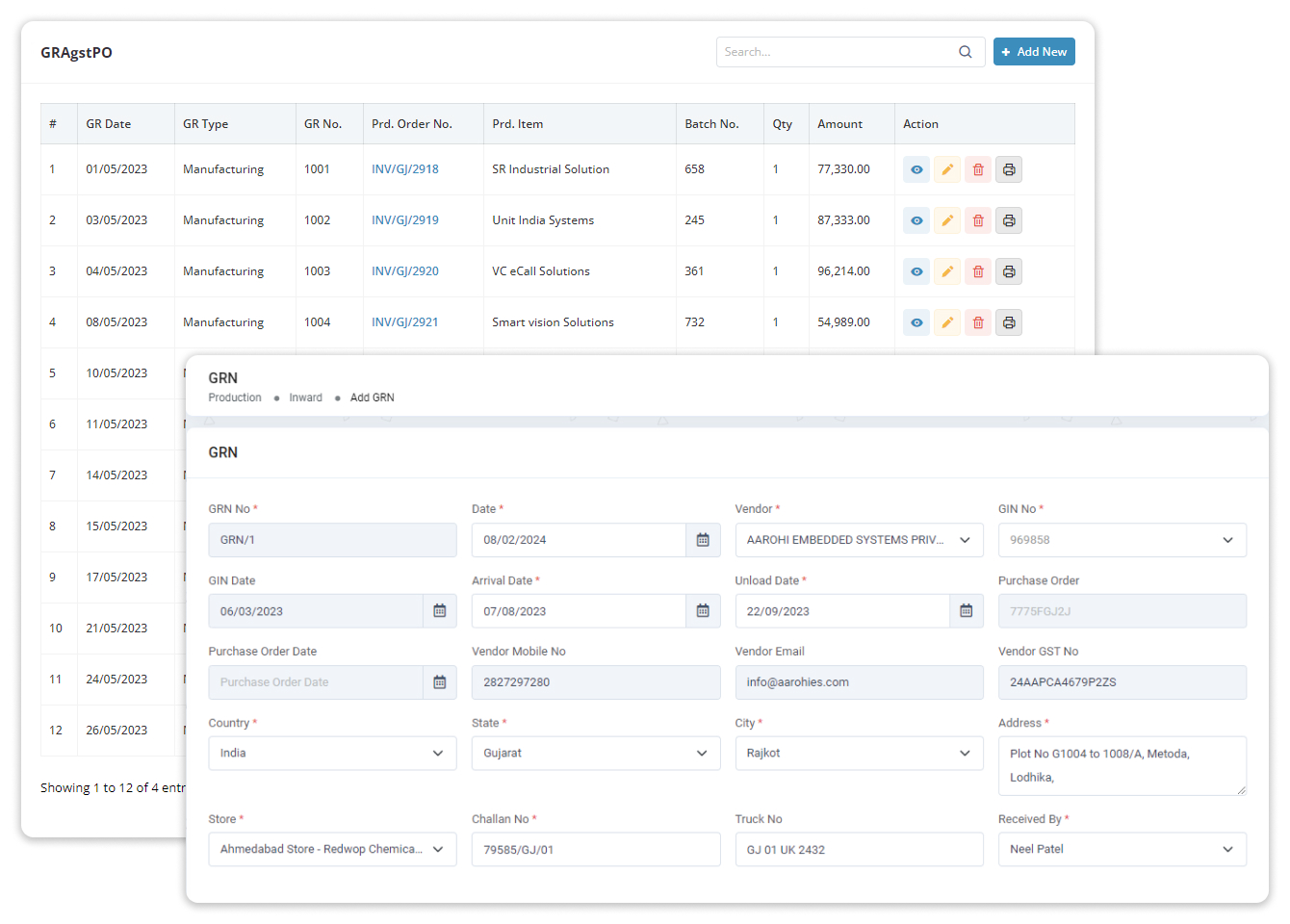

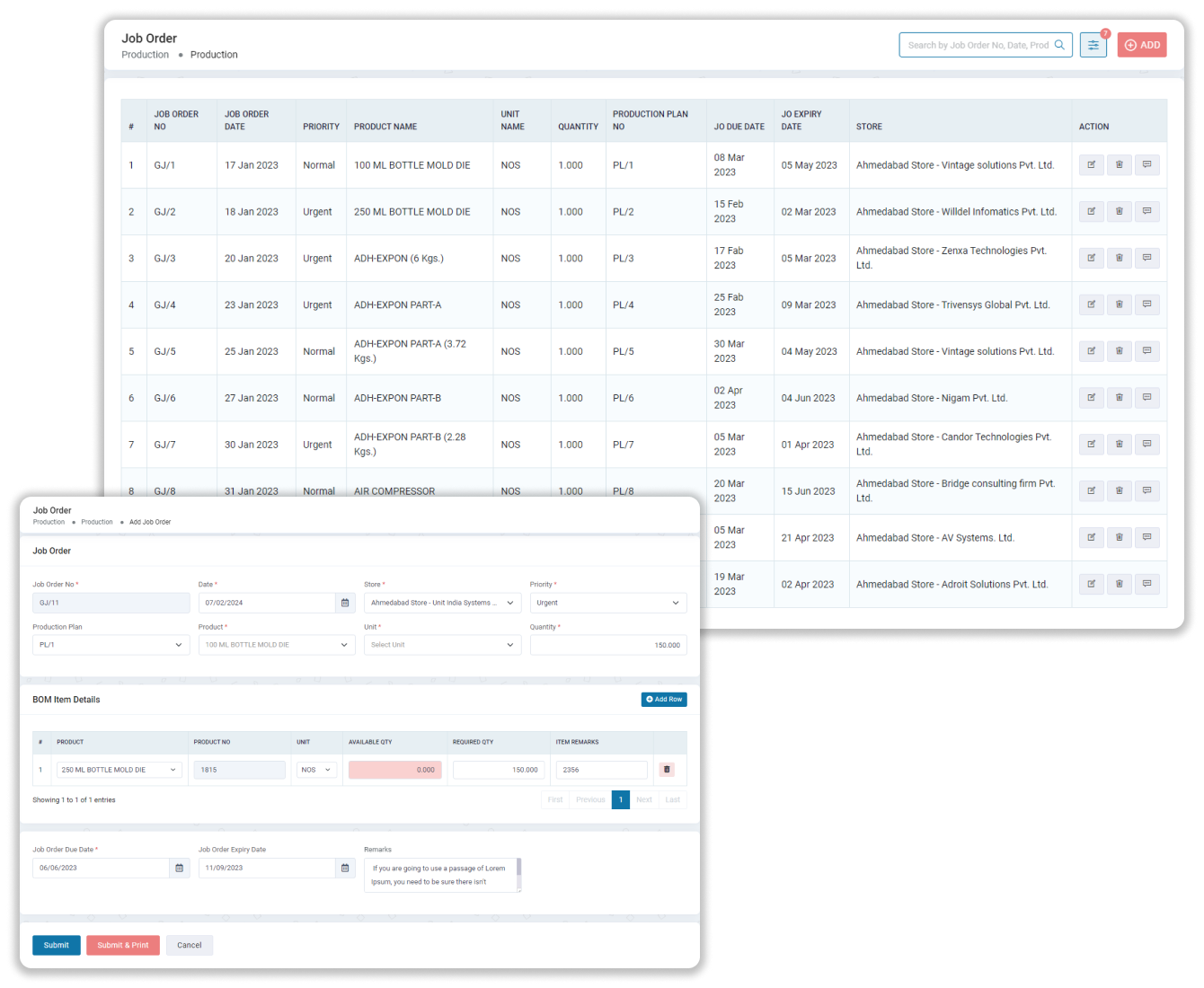

Empower Production Control with Dynamic Orders

- Efficient Order Management: Streamline order creation and management processes, ensuring precision and efficiency in executing production tasks for timely and accurate fulfillment of customer demands.

- Real-time Progress Tracking: Monitor production orders in real-time, gaining instant visibility into progress. Facilitate quick decision-making and proactively address any delays, optimizing overall production timelines and customer satisfaction.

- Resource Optimization: Enhance resource efficiency by aligning production orders with available resources. Minimizing waste and maximizing productivity is now a breeze as you can optimize workforce, equipment, and materials. This will ensure a cost-effective and streamlined production process.

- Adaptive Workflows: Enable adaptive workflows for production orders, accommodating changes seamlessly. This flexibility enhances responsiveness to market demands, ensuring agile and efficient production processes that meet evolving customer needs effectively.

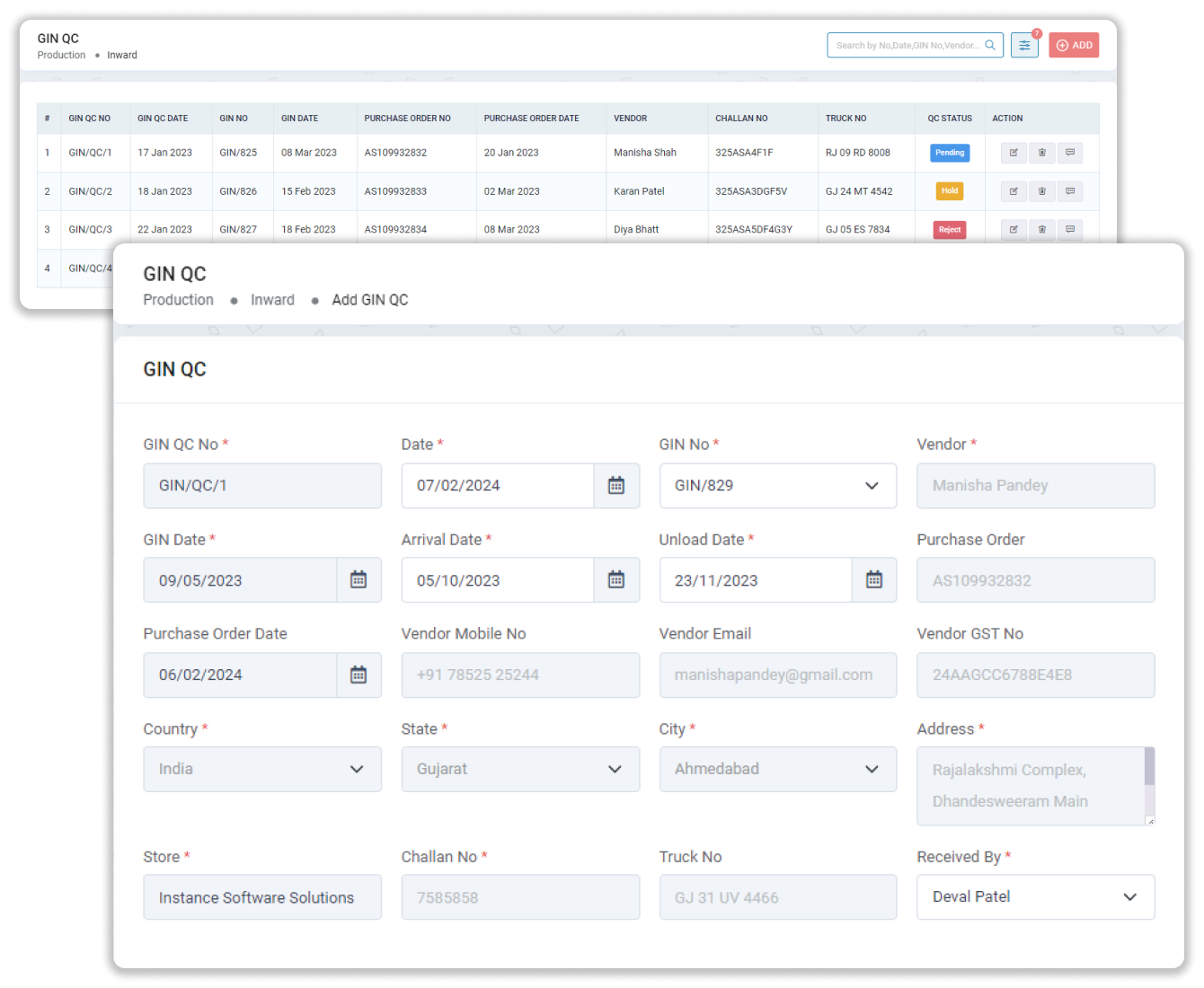

Elevate Quality Assurance with Robust Controls

- Rigorous Quality Checks: Implement thorough and rigorous quality checks at every step of the production. Also, ensure compliance with standards and timely delivery of products of top-notch quality and reliability.

- Real-time Monitoring of Metrics: Monitor quality metrics in real-time, enabling proactive identification and rectification in case there are any deviations. This real-time insight ensures consistent product quality and also eliminates the risk of any defects or errors.

- Efficient Defect Resolution: Facilitate swift defect resolution through streamlined processes. Identify and address issues promptly. Also, witness reduced production disruptions & ensure customer satisfaction through defect-free products.

- Data-Driven Improvement: Make your production ecosystem data-driven for continuous improvement initiatives. Besides, you can analyze trends and identify root causes of issues to implement corrective measures for improved production quality.