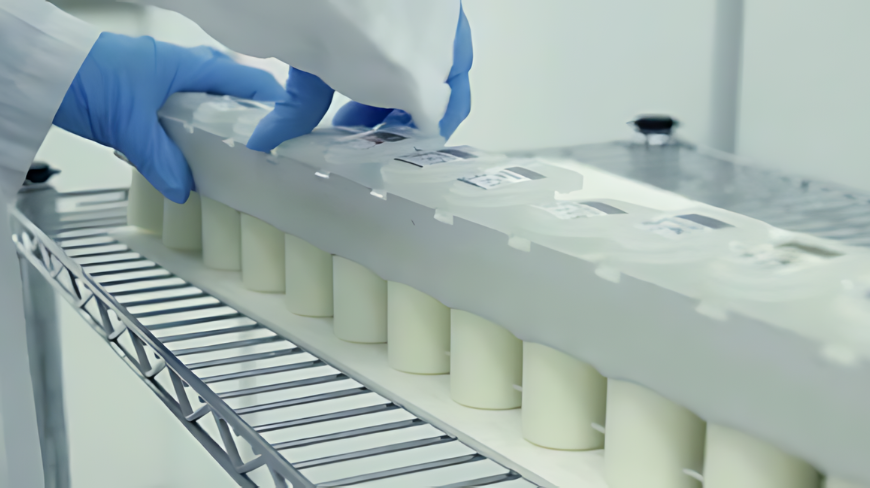

The dairy industry is constantly evolving, and packaging plays a crucial role in ensuring that dairy products are safe, fresh, and ready to reach the market. However, the packaging process can be complex and time-consuming, involving multiple steps that need to be executed with precision to meet customer demand and industry standards. This is where a Dairy ERP system comes into play, offering a streamlined approach to managing packaging processes, making it easier for dairy businesses to get their products market-ready.

Why Is Packaging Important in the Dairy Industry?

Packaging in the dairy industry is not just about putting products into containers. It serves several vital functions:

- Protecting Products:Packaging helps keep dairy products like milk, cheese, yogurt, and butter safe from contamination and spoilage. It acts as a barrier against external factors such as air, light, and bacteria.

- Preserving Freshness:Proper packaging ensures that dairy products stay fresh for as long as possible, extending their shelf life and reducing food waste.

- Meeting Regulations:Dairy products need to comply with strict regulations regarding labeling, expiration dates, and food safety. Packaging plays a key role in ensuring these requirements are met.

- Marketing and Branding:The packaging is often the first thing a customer notices. It carries the company’s branding and product information, making it an essential part of marketing efforts.

Given the importance of packaging, dairy businesses must ensure that their packaging processes are streamlined, efficient, and error-free. This is where Dairy ERP systems make a difference.

How Dairy ERP Systems Improve Packaging Processes

1. Better Inventory Management

One of the biggest challenges in packaging is ensuring that all the materials needed—such as cartons, labels, and containers—are available when needed. Running out of packaging materials can delay the entire production process and result in missed deadlines.

A Dairy ERP system helps manage inventory effectively by tracking stock levels in real-time. This means businesses can always know when packaging materials are running low and can automatically reorder them before they run out. This prevents delays and ensures that packaging operations run smoothly without interruptions.

For example, if a dairy business is producing a large batch of milk, the ERP system will monitor the stock of milk cartons and notify the team if more cartons are needed. This allows the business to order more packaging materials in advance, avoiding any delays.

2. Improved Quality Control

Ensuring that dairy products are packaged correctly is essential for maintaining product quality and meeting regulatory standards. ERP for dairy automates quality control checks at every stage of the packaging process, from sealing containers to ensuring that labels are applied accurately.

The ERP system can also monitor packaging lines to ensure that the right quantity of product is packed in each container and that the packaging is sealed properly. If any issues are detected, the system sends alerts, allowing workers to fix the problem before the product is shipped to customers.

For example, if a batch of yogurt is not sealed correctly, the ERP system will flag the issue, preventing the defective products from reaching the market. This helps maintain product quality and reduces the risk of customer complaints or product recalls.

3. Regulatory Compliance and Traceability

The dairy industry is subject to strict regulations regarding food safety, labeling, and packaging. Dairy ERP ensures that all packaging operations comply with these regulations by automating processes such as labeling and documentation.

One key benefit is Dairy ERP enhances product traceability. With a robust ERP system, businesses can easily track each product's journey from production through to packaging and distribution. This is especially important in case of a product recall, as the system can trace the specific batch that needs to be recalled, ensuring a quick and efficient response.

4. Automated Packaging Schedules

Packaging processes need to be aligned with production schedules to ensure that products are packaged and ready for delivery on time. Dairy ERP solutions automate packaging schedules based on production levels and demand forecasts, ensuring that packaging operations are always in sync with production output.

For instance, if demand for a particular dairy product increases during a holiday season, the ERP system can automatically adjust packaging schedules to ensure that enough products are packaged to meet the demand. This level of automation reduces the risk of bottlenecks and ensures that products are ready for market when needed.

5. Cost Efficiency and Waste Reduction

ERP software for dairy industries helps businesses optimize their packaging processes by reducing waste and improving cost efficiency. By automating tasks such as inventory management and quality control, ERP systems reduce the likelihood of human error, which can lead to packaging defects or overproduction.

ERP systems also provide detailed cost analysis reports, allowing businesses to track expenses related to packaging materials, labor, and equipment. This enables businesses to identify areas where costs can be reduced and implement strategies to improve profitability.

For example, if a dairy business finds that it is using more packaging materials than necessary, the ERP system can provide data that helps the business switch to more cost-effective or eco-friendly alternatives, reducing both costs and environmental impact.

6. Seamless Integration with the Supply Chain

ERP for dairy integrates packaging processes with the broader supply chain, ensuring that packaged products are promptly moved to the next stage—whether it’s storage, transportation, or distribution.

For example, once a batch of milk is packaged, the ERP system can automatically generate shipping labels, schedule transportation, and update inventory levels across distribution centers. This seamless integration minimizes delays and ensures that dairy products are delivered to retailers or customers quickly and efficiently.

7. Real-time Data and Reporting

Dairy ERP provides real-time data on packaging processes, allowing businesses to monitor performance and make informed decisions. Managers can access detailed reports on packaging output, material usage, and labor efficiency, helping them identify trends and optimize operations.

Real-time data also enables quick adjustments to packaging processes in response to market demand, ensuring that dairy products are always available to consumers when needed.

The Benefits of Dairy ERP in Packaging

- Increased Efficiency:It automates manual tasks, speeding up the packaging process and reducing human errors, which leads to faster market readiness.

- Enhanced Accuracy:Automated quality checks and real-time monitoring ensure that packaging operations meet regulatory and quality standards consistently.

- Cost Savings:By reducing material waste, minimizing labor costs, and optimizing resource usage, It helps businesses save money.

- Improved Flexibility:Dairy ERP systems allow businesses to quickly adapt to changes in demand or production levels, ensuring that packaging operations remain efficient.

- Competitive Advantage:Streamlining packaging processes helps dairy businesses get their products to market faster, giving them a competitive edge in the industry.

Conclusion:

Dairy ERP system is essential for streamlining packaging processes in the dairy industry. By integrating various functions like inventory management, quality control, regulatory compliance, and supply chain management, ERP systems ensure that dairy products are packaged efficiently, safely, and cost-effectively. Consider the case study of a prominent dairy company that adopted a Dairy ERP system to address their challenges.

For dairy businesses looking to improve their packaging operations and gain a competitive advantage in the market, investing in a Dairy ERP is a smart move. It not only reduces costs and waste but also ensures that products are market-ready in a timely and efficient manner, allowing businesses to meet customer demand and succeed in the ever-evolving dairy industry.